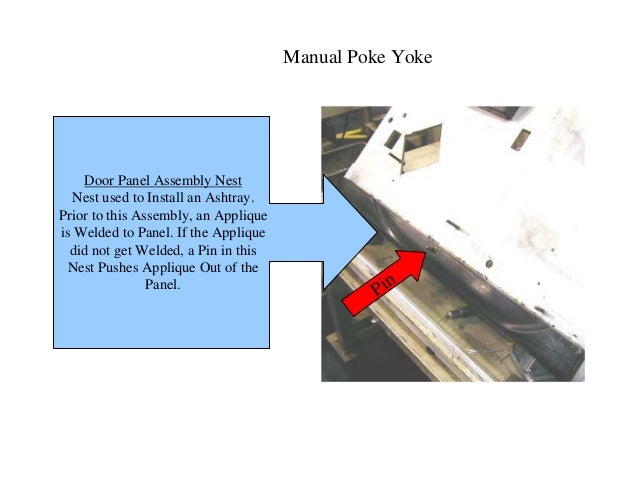

Details Of Poka Yoke Manual

The following are my inputs to a discussion on AME’s LinkedIn group initiated last August by, which also included contributions from, and. When to use Poka-Yoke Poka-Yokes prevent human error, and are therefore relevant when and only when human error is the main cause of your quality problems.

If you have process capability issues, focus on resolving them, not on preventing human error. What you need is deep understanding of your technology combined with statistical tools to enable your process to consistently hold tolerances. If your process is capable but you are still producing in batches, focus on converting to flow to prevent your defectives being buried in WIP.

This step-by-step guide provides the directions for performing poka-yoke techniques to processes.

Your problem is that it takes you too long to detect problems, not human error. If your process is capable and you practice one-piece flow, then the defects you still produce are due to human error. At this point, and not before, Poka-Yoke is the relevant technique. For details, see. Poka-Yokes do not require extensive a-priori analysis Poka-Yokes are usually small devices, such as a permanent magnet to suck up a panel already containing a metal bracket, or a hole in a container to prevent overfill.

Doing an FMEA do decide whether to design and implement a Poka-Yoke is more expensive than just doing it. If you sort of think a process might need a Poka-Yoke and you have an idea of what it might be, just go ahead, try it, and document it in your company-specific Poka-Yoke library to inspire others. Don’t over-analyze it upfront.

- Find here details of companies selling Poka Yoke System, for your purchase requirements. Get latest info on Poka Yoke System, suppliers, manufacturers, wholesalers, traders with Poka Yoke System prices for buying.

- ・Product details page. “POKA-YOKE,” to indicate the importance of this manufacturing challenge. ◇Refer to and confirm by the manual for details.

On the other hand, if you are building a spacecraft, you should definitely do an FMEA. If it adds labor, it’s not a Poka-Yoke By definition, also a Poka-Yoke device adds no labor. Manually scanned barcodes on parts to validate picks, for example, do not qualify as a Poka-Yokes because they add labor. A barcode that is automatically read or an RFID tag, on the other hand, would qualify. A Poka-Yoke has to become part of the process in the long run. If you look at the old you will notice that none of the examples adds labor, and there is a reason: any device that adds labor is likely to be bypassed under pressure. This even happens with safety.

Take, for example, the traditional approach of requiring the pressing of two buttons to start a press. How many times to you see plants where one button is taped down so that you can start the press with just the other one?

By contrast, safety light curtains add no labor, and are not bypassed. Using bar codes reading for data acquisition effectively eliminates the errors due to keyboarding because it is faster. If it weren’t, operators would revert to keyboarding and typos would creep back in.

This is exactly what you see happening after two or three failed attempts at scanning a code. A barcode on a workpiece that is automatically read can be a Poka-Yoke.

The workpiece passes under a reader in the proper orientation and under good lighting conditions and the barcode is reliably read. Under these conditions, it can even drive the lighting of the proper bins in a pick-to-light system. It does not work as a Poka-Yoke s if an operator has to wave a bar code gun in front of a part for pick validation. Just because you use a device with the intent of preventing mistakes doesn’t mean it works.

You have to make sure it does, and not just at the time you implement it. If you don’t pay attention, Poka-Yokes tend to deteriorate and to be set aside, for example when new operators are assigned to the station. Fascinated with the art of making things, Michel is working to improve it. Trained in engineering and applied math, he got his feet wet in production in the early 1980s, and later apprenticed under master Japanese consultant Kei Abe for eight years, starting his own group in 1996. He has been consulting since 1987, teaching courses and writing technical books.

He intends to keep working with like-minded partners in the Takt Times Group and contributing improvements in the management and technology of manufacturing as a consultant, trainer, and writer. Personal Links. Verified Services.

The aim of mistake-proofing is to remove the need for people to think about the products or processes they are using. This is because the products have a design that makes it impossible to use them in the wrong way. When someone uses the product the wrong way, it does not function and it becomes obvious to the user that they are doing the wrong thing. The simple yet effective design features make it difficult for errors to occur during usage of the product.

Origin and Application The concept developed out of the need to achieve quality in production processes. It was Shigeo Shingo, one of the pioneers of the Toyota Production System, who proposed the concept. He was a quality guru who proposed the idea of ‘Zero Defects’ as a quality paradigm. The thinking was that a process should be able to detect and prevent errors from occurring. This would lead to a final product of high quality. Many people lose their lives or get maimed through vehicular accidents each year.

Safety of users of automobiles is of paramount importance and many measures have been taken to make them safe. The following are examples of mistake-proofing in the automotive industry:.

Radar and video cameras in new vehicle models are able to tell the distance and speed of other road users. This helps them prevent collisions in case of sudden stops.

The device here is more of a warning and preventive measure but it does not strictly fit into the concept of behaviour modification. The driver may choose to ignore the warning which will lead to an accident. The device does not stop the accident from happening in the first place. Automatic breaking system stops the vehicle in case the driver fails to brake when an obstacle suddenly appears on the road.

If the system above is used with this device, it will be a better preventive measure as the system will note that a warning has been ignored. The sensors will then kick in and stop the vehicle - a key component of poka yoke is at play here. Electronic stability control helps reduce the possibility of accidents that can occur when a vehicle skids uncontrollably due to over-steering by the driver. The condition being controlled here is the slippery road - when this condition comes into play the system kicks in to prevent an unwanted result from occurring. Cross-traffic alerts warn drivers of impending traffic when they are reversing from a parking position. Like the first example of mistake-proofing in the automotive sector, this device is more of a warning and must be used in-conjunction with other devices to be successful.

Adaptive headlights are able to respond to the conditions on the road so as to assist the driver have better visibility. For example, they are able to illuminate curved roads and also during bad weather. Airbags deflate quickly after an accident to prevent injury to the occupants of the vehicle. Seat belt pre-tensioners assist in holding the passenger in place in case of an accident and prevent them from sliding through. Child resistant tops for medicines and household chemicals makes it difficult for children to consume the contents.

Poka Yoke Pronunciation

Elevator doors have a sensor that causes them to open when there is an obstruction-this prevents injury to someone trying to enter as the doors are closing. Box cutters have a retractable blade that only pops out when the handle is held. Lawn mowers have a safety bar on the handle that when released, switches off the machine. Circuit breakers in the home electrical system prevent electrical overloads.

Overflow outlets in bathroom and kitchen sinks prevent flooding of the house when the drain is blocked. The Door of a washing machine or dryer makes the machine stop when it is opened, so as to prevent injury from accidents.

In lean manufacturing systems, poka yoke also includes a philosophy of constantly working to prevent mistakes from occurring in the first place. The internal processes in lean manufacturing systems are supposed to produce quality products the first time. Error-proofing in this case is a quality assurance technique that ensures quality is in-built and results in better products. For the final product to be of high quality, all the inter-connected process steps have to give first time quality. If an mistake or defect is allowed to move to the next step, the likelihood of it appearing in the finished product is very high. It is therefore necessary to develop ways of preventing a defective product moving to downstream process.

This is important because a finished product is considered to be the most expensive form of inventory due to the accumulated costs along the value chain. If a defect occurs in the finished product, the costs of production increase due to the effort required to correct it. Magnets in a grain packaging plant detect and remove metal pieces before they are packed.

Interlock switches which detect the position of a machine guard and switch off the machine when the guard is lifted. The machine will never operate when the guard has been lifted and this prevents accidents to the operator. Light curtains in a factory detect when someone is near very dangerous machines and switches off the machine to prevent injuries. Safety mats near machine areas that pose a danger automatically trigger stoppage when someone steps on them. This prevents injury to personnel (such are technicians) who are trying to access dangerous sections of a machine. Power guards on high inertia machines with moving parts prevent opening until the parts have stopped completely in order to prevent accidents.

Machines that must be controlled using both hands ensure that some distance is kept between the operator and dangerous machine parts. In the food industry, gloves and other small pieces of personal protective equipment must be blue in colour for ease of detection in case they fall into food. This is because blue foods are rare in nature and the color difference makes it easy to detect that a foreign object has fallen into the food. Using standardized containers at the workstation enables workers to know exact quantities without having to weigh or count the contents.

Use of colour coded date labels to mark the production dates of products. This way the different batches are easily identifiable for the purpose of product rotation. The system is especially useful in the food industry where rotation of batches is very important because of hygiene considerations. There are many other examples of products that have fool-proofing ranging from USB cables to child proof sockets. Here are a few examples:. Glow-in-the-dark strips around the toilet bowl prevent users from urinating on the sides.

Mop slippers save time for the busy person as they prepare to go to work or school. Scrap collecting bowl has a ledge that is attached to the table top to collect vegetable scraps before they fall on the ground. Oven rack guard prevents accidental burns as one is removing food from the oven chamber. Locator stickers that are put on commonly lost items such as keys and can be traced using the phone.

Upside-down tomato sauce bottles enable the consumer to use up all the tomato sauce and also lets the water that collects at the bottom come out first. Mobile phones are designed in such a way that when they fall, the cover separates so as to minimise the shock that would damage them. Color-coding of electrical wires is meant to prevent short circuiting that can occur if they are not matched properly. that prevent someone from drinking too much. A company invented a too much thus preventing you from getting over-weight.

Mistake-proofing also occurs in natural systems and the human body system is a good example of how it works to prevent errors from occurring:. Coughing is a natural reaction that prevents the error of foreign bodies from entering into the lungs. The sensitive wall linings of the respiratory tract detect and eject minute particles through coughing. Veins have valves that are designed to prevent the error of back-flow of blood as it travels through the system. They also allow some blood to collect within the system without busting as they have a larger internal diameter.

Arteries have thick walls that can withstand the high pressure that blood from the heart exerts on the circulatory system. Tearing is a necessary reaction to the entry of foreign bodies into the eye. Mucus membrane traps bacteria and prevents the error of pathogens entering the system. The skin is the first defence against entry of foreign bodies and the oils and enzymes prevent harmful bacteria into the human body.

Inflammation reaction of swelling happens when blood vessels leak fluid into the tissues. The chemicals attract white blood cells (phagocytes) that eat germs and dead/ damaged cells. This reaction prevents the spread of harmful toxins and pathogens to the rest of the human body and is a form of natural error-proofing. The space industry requires accurate procedures to be constantly carried out so as to ensure the successful completion of space missions.

Any small error in the implementation of these procedures can lead to a major disaster. The industry has therefore developed many mistake-proofing devices to prevent errors from occurring and this has resulted in the high success rates of space mission over the years. The following are a few examples of error-proofing in the space industry:. Escape capsule is designed to help the astronauts safely return to earth in case if there is an emergency during launch of the spacecraft.

An abort motor fires over half a million pounds of thrust to steer the capsule away from the booster rocket. Another motor steers the capsule in the right direction and then a jettison motor separates the escape rocket from the capsule which has parachutes to allow it to safely land on earth. This error proofing device will save lives in case the launch of the rocket fails. Checklists used in the pre-flight preparation are detailed and are designed to ensure all the parameters are within the allowed range before the flight can commence. Nuclear accidents can have devastating effects as was seen in the Chernobyl disaster. Nuclear power plants use the concept of barriers to the prevent fission material from being released from the reactor core to the environment.

The fuel rods have cladding that prevent the release of fission material in the event of a melt-down. The reactor is designed to assist in the cooling of the rods in case there is a decrease in the cooling water in the core. This is very important as the heat released during the decay of radioactive material can start a chain reaction that is unstoppable. The service industry is very important in that there is direct and constant interaction with the customer and any failure on the part of providers of services can result in losing good business. This failure to serve a customer as per their expectation can be considered an error and many service providers have put in place a number of error-proofing processes to prevent this from happening.

The following are just a few examples of how service providers mitigate against the chances of causing mistakes in their businesses:. Electronic tags in airline luggage handling systems ensure that passenger luggage is not lost after check-in. Airline staff are able to locate misplaced luggage anywhere in the world as the tag contains all the necessary passenger and flight information that is used in tracking it. Electronic waiter pads in restaurants ensure that the right order goes to the right table at the shortest possible time. This order matching technology prevents the error of waiters taking the wrong order and also enhances fast delivery to the customer. Queue management systems in banks and other public venues are designed in such a way that customers are served according to the order in which they came in promptly thus preventing customer dissatisfaction.

The fact that air travel is considered to be safer than road travel can be attributed to a number of fool-proofing devices that have been put in place over the years. While air accidents still occur, they have significantly been reduced because of these devices:. De-icing chemicals make it difficult for ice to form on the wings of aeroplanes which can cause serious accidents. Auto-pilot keeps the plane flying in case of inclement weather or when the pilot is ill-disposed. Captain meals on planes must be different from the meals served to other passengers so as to prevent cases of food poisoning affecting the pilot, which can be very dangerous especially mid-flight. Fuel jettisoning is an important procedure during emergency landings as it prevents major fires from the fuel held in the tanks.

Instrument control-panel is located in such a manner that the pilot and engineer are able to view all readings easily. From the above comprehensive list of examples, it becomes obvious that there are certain characteristics of error-proofing devices that help in achieving the aims of mistake-proofing. These characteristics include:. Simplicity, which means that the solutions are not complex and unambiguously resolve the problem of error occurring.

Jidoka

Automatic Nature: they do not require any further intervention from the person using the device. Safety is a key characteristic of poka yoke devices in that they also prevent the users from injuries. Feedback is immediate in the case of failure when the conditions go out of specification. Quality is ingrained in the process and the solutions encourage the right methods to be used by operators of the devices. It is a way of standardizing the correct methods of performing a process. Location at the source of a potential problem within a process. Reduction in the number of process steps required to complete a process as the inspection aspect is minimized or completely eliminated.

Show Details Necessary HubPages Device ID This is used to identify particular browsers or devices when the access the service, and is used for security reasons. Login This is necessary to sign in to the HubPages Service. Google Recaptcha This is used to prevent bots and spam. Akismet This is used to detect comment spam. HubPages Google Analytics This is used to provide data on traffic to our website, all personally identifyable data is anonymized. HubPages Traffic Pixel This is used to collect data on traffic to articles and other pages on our site. Unless you are signed in to a HubPages account, all personally identifiable information is anonymized.

Amazon Web Services This is a cloud services platform that we used to host our service. Cloudflare This is a cloud CDN service that we use to efficiently deliver files required for our service to operate such as javascript, cascading style sheets, images, and videos. Google Hosted Libraries Javascript software libraries such as jQuery are loaded at endpoints on the googleapis.com or gstatic.com domains, for performance and efficiency reasons. Features Google Custom Search This is feature allows you to search the site. Google Maps Some articles have Google Maps embedded in them. Google Charts This is used to display charts and graphs on articles and the author center. Google AdSense Host API This service allows you to sign up for or associate a Google AdSense account with HubPages, so that you can earn money from ads on your articles.

No data is shared unless you engage with this feature. Google YouTube Some articles have YouTube videos embedded in them. Vimeo Some articles have Vimeo videos embedded in them. Paypal This is used for a registered author who enrolls in the HubPages Earnings program and requests to be paid via PayPal. No data is shared with Paypal unless you engage with this feature. Facebook Login You can use this to streamline signing up for, or signing in to your Hubpages account. No data is shared with Facebook unless you engage with this feature.

Maven This supports the Maven widget and search functionality. Marketing Google AdSense This is an ad network. Google DoubleClick Google provides ad serving technology and runs an ad network. Index Exchange This is an ad network. Sovrn This is an ad network. Facebook Ads This is an ad network.

Amazon Unified Ad Marketplace This is an ad network. AppNexus This is an ad network. Openx This is an ad network.

Rubicon Project This is an ad network. TripleLift This is an ad network. Say Media We partner with Say Media to deliver ad campaigns on our sites. Remarketing Pixels We may use remarketing pixels from advertising networks such as Google AdWords, Bing Ads, and Facebook in order to advertise the HubPages Service to people that have visited our sites. Conversion Tracking Pixels We may use conversion tracking pixels from advertising networks such as Google AdWords, Bing Ads, and Facebook in order to identify when an advertisement has successfully resulted in the desired action, such as signing up for the HubPages Service or publishing an article on the HubPages Service. Statistics Author Google Analytics This is used to provide traffic data and reports to the authors of articles on the HubPages Service.

Comscore ComScore is a media measurement and analytics company providing marketing data and analytics to enterprises, media and advertising agencies, and publishers. Non-consent will result in ComScore only processing obfuscated personal data. Amazon Tracking Pixel Some articles display amazon products as part of the Amazon Affiliate program, this pixel provides traffic statistics for those products.